What’s New

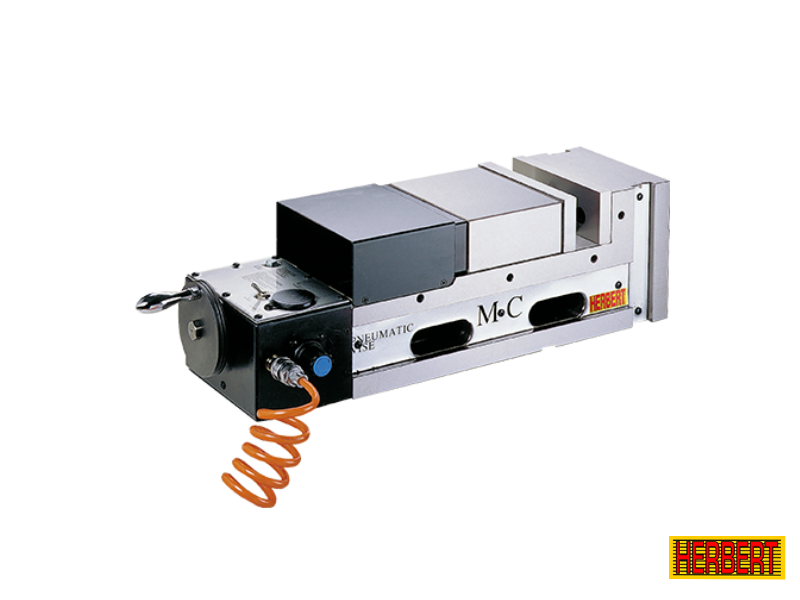

MVS-Pneumatic MC Precision Angle-Fixed Vise for Automated Equipment Manufacturing

Introduction:

In the dynamic landscape of automated equipment manufacturing, the choice of workholding solutions can significantly impact efficiency, precision, and overall productivity. One innovative solution gaining attention is the MVS-Pneumatic MC Precision Angle-Fixed Vise by Herbert. This article explores the features and benefits of the MVS series, shedding light on how it aligns with the needs of automated equipment manufacturers currently evaluating its integration.

Key Features of the MVS-Pneumatic MC Precision Angle-Fixed Vise:

- Pneumatic Power: The MVS series utilizes pneumatic technology to provide robust clamping. Pneumatic systems offer quick and reliable actuation, contributing to swift workpiece changes and minimizing downtime.

- Precision Angle-Fixed Design: The precision angle-fixed design ensures accuracy in machining. This feature is particularly crucial in automated equipment manufacturing, where consistent precision is vital for the seamless operation of robotic arms and other automated systems.

- Versatile Clamping: The MVS-Pneumatic MC Vise is designed to accommodate a variety of workpieces. Its versatile clamping capabilities make it suitable for holding different shapes and sizes, providing flexibility in automated production setups.

- High-Quality Construction: Herbert is renowned for its commitment to quality construction. The MVS series is no exception, featuring durable materials and precise engineering to withstand the demands of automated machining processes.

Benefits for Automated Equipment Manufacturers:

- Increased Automation Efficiency: The pneumatic actuation of the MVS-Pneumatic MC Vise aligns seamlessly with automated manufacturing processes. It enables rapid clamping and unclamping, supporting the continuous workflow essential for automated equipment production.

- Consistent Precision: The precision angle-fixed design ensures that each workpiece is securely and accurately held in place. This consistency is paramount in automated setups where deviations can lead to errors in the production chain.

- Reduced Downtime: Swift workpiece changes and reliable clamping contribute to reduced downtime. In automated manufacturing, where efficiency is directly linked to output, any reduction in downtime translates to improved productivity.

- Adaptability to Various Workpieces: The MVS series' versatility in clamping different workpiece geometries is advantageous for manufacturers dealing with diverse product lines. It streamlines the production process by offering a single solution for various machining needs.

Application Scenarios in Automated Equipment Manufacturing:

- Robotic Arm Integration: The MVS-Pneumatic MC Vise is well-suited for integration with robotic arms. Its precision and adaptability make it an ideal choice for workholding in scenarios where robotic arms handle multiple machining tasks.

- Continuous Production Lines: Automated production lines often demand uninterrupted workflows. The MVS series' pneumatic efficiency and reliable clamping contribute to the continuous operation of production lines.

- Multi-Tasking Machining Centers: In automated machining centers handling multi-tasking operations, the MVS-Pneumatic MC Vise's versatility shines. It accommodates the changing requirements of different machining tasks without compromising on precision.

Conclusion:

For automated equipment manufacturers navigating the complexities of modern manufacturing, the MVS-Pneumatic MC Precision Angle-Fixed Vise emerges as a valuable asset. Its pneumatic power, precision angle-fixed design, and versatile clamping capabilities align seamlessly with the demands of automated production environments. By considering the MVS series, manufacturers can optimize efficiency, enhance precision, and pave the way for a streamlined and productive automated manufacturing process.

As Herbert continues to innovate in workholding solutions, the MVS-Pneumatic MC Vise stands as a testament to their commitment to providing cutting-edge solutions that meet the evolving needs of the manufacturing industry. For automated equipment manufacturers seeking excellence in workholding, the MVS series promises to be a reliable and efficient choice.

Contact us for more information about MVS Pneumatic MC Vise