What’s New

The H-Quick Change System Pallet in Workholding

In today's fast-paced manufacturing world, efficiency is the name of the game. Quick change systems have become indispensable tools for modern machining processes. They streamline workpiece changeovers, reduce downtime, and boost productivity. Within this realm of workholding, the H-Quick Change System Pallet offered by Herbert is a game-changer. This article delves deep into the world of Quick Change Systems, exploring their importance, and focuses on the H-Quick Change System Pallet as a star component.

Understanding Quick Change Systems

Quick Change Systems are a family of workholding solutions designed to expedite the setup, changeover, and removal of workpieces on machining tools. They are pivotal in modern manufacturing, allowing businesses to remain agile and competitive in a dynamic marketplace. These systems typically consist of several components, including pallets, clamping modules, and base plates.

The Role of the Pallet

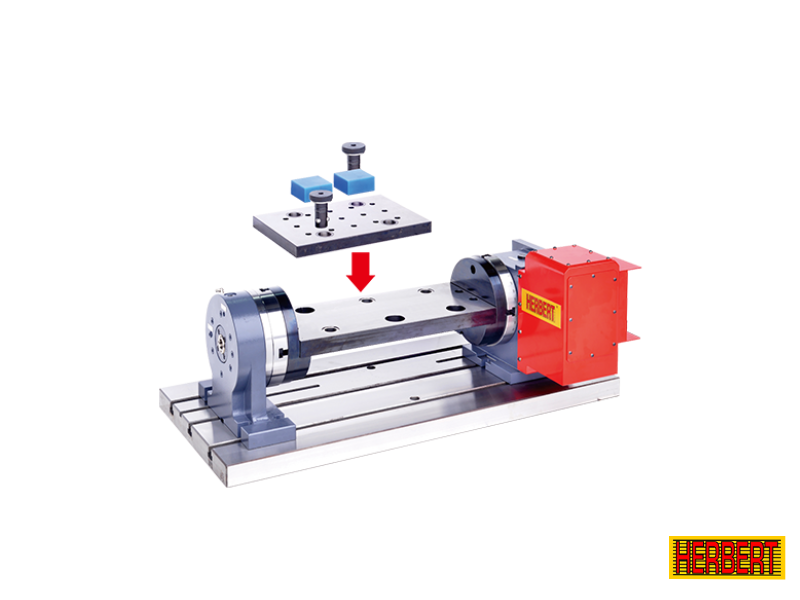

The pallet is the centerpiece of Quick Change Systems. It serves as the foundation for securely mounting workpieces, fixtures, or tooling. Pallets are engineered to facilitate rapid changeovers. Herbert's H-Quick Change System Pallet takes this role to the next level with precision engineering and a focus on durability.

Herbert's H-Quick Change System Pallet: A Closer Look

- Precision Engineering: Herbert's H-Quick Change System Pallet is a masterpiece of precision engineering. It is meticulously crafted to exacting standards to ensure a secure, accurate, and repeatable workpiece setup. This level of precision is instrumental in delivering high-quality machining results consistently.

- Robust Construction: The durability of Herbert's H-Quick Change System Pallet is beyond compare. Its robust construction guarantees stability and resistance to wear and tear. In machining, where stability is key to precision, this is a game-changer.

- Quick Change Capabilities: The H-Quick Change System Pallet lives up to its name by offering rapid workpiece change capabilities. It boasts a tool-free design, allowing operators to efficiently mount and dismount workpieces, fixtures, or tooling with minimal effort. This feature minimizes downtime and maximizes productivity.

Applications Across Industries

Quick Change Systems, including the H-Quick Change System Pallet, are versatile solutions applied across various industries to enhance efficiency and productivity. Here are some key sectors where these systems are making a significant impact:

1. Aerospace Industry

In aerospace manufacturing, precision and efficiency are paramount. The H-Quick Change System Pallet finds application in machining complex components such as turbine blades, aircraft structural parts, and engine components. This precision and speed contribute to on-time production schedules.

2. Automotive Industry

The automotive sector thrives on high-volume production and tight schedules. Here, the H-Quick Change System Pallet is instrumental in machining engine blocks, cylinder heads, transmission components, and other critical automotive parts, ensuring efficient production with rapid workpiece changeovers.

3. General Manufacturing

General manufacturing encompasses a wide range of applications, including milling, drilling, grinding, and turning operations. Quick Change Systems offer a universal advantage by reducing setup times and increasing throughput.

4. Tool and Die Industry

The tool and die industry relies on precision, accuracy, and repeatability. Quick Change Systems, featuring the H-Quick Change System Pallet, shine in machining dies, molds, and other workpieces requiring precise positioning and repeatable clamping. This efficiency streamlines the production of complex, high-precision components.

Conclusion

The H-Quick Change System Pallet, a flagship product from Herbert, exemplifies how modern manufacturing is embracing quick change systems to improve efficiency, reduce downtime, and enhance productivity. It plays a pivotal role in aerospace, automotive, general manufacturing, and the tool and die industries, ensuring consistent, high-quality results across a multitude of applications.

Quick Change Systems, with components like the H-Quick Change System Pallet, are revolutionizing the manufacturing landscape. They are integral to achieving operational excellence in an era where time is money, and precision is non-negotiable. By adopting these systems, businesses can keep pace with market demands and maintain a competitive edge. Herbert's commitment to precision engineering and quality construction has cemented their position as a trusted provider of these innovative solutions, supporting manufacturers in their quest for operational excellence.

Efficiency and precision are no longer a choice but a necessity in modern manufacturing. Quick Change Systems like the H-Quick Change System Pallet are the tools of the trade, paving the way for streamlined, agile, and competitive operations. As the manufacturing world continues to evolve, embracing these systems is a clear path towards success with Herbert at your side, ensuring that every workholding challenge is met with innovative and efficient solutions.